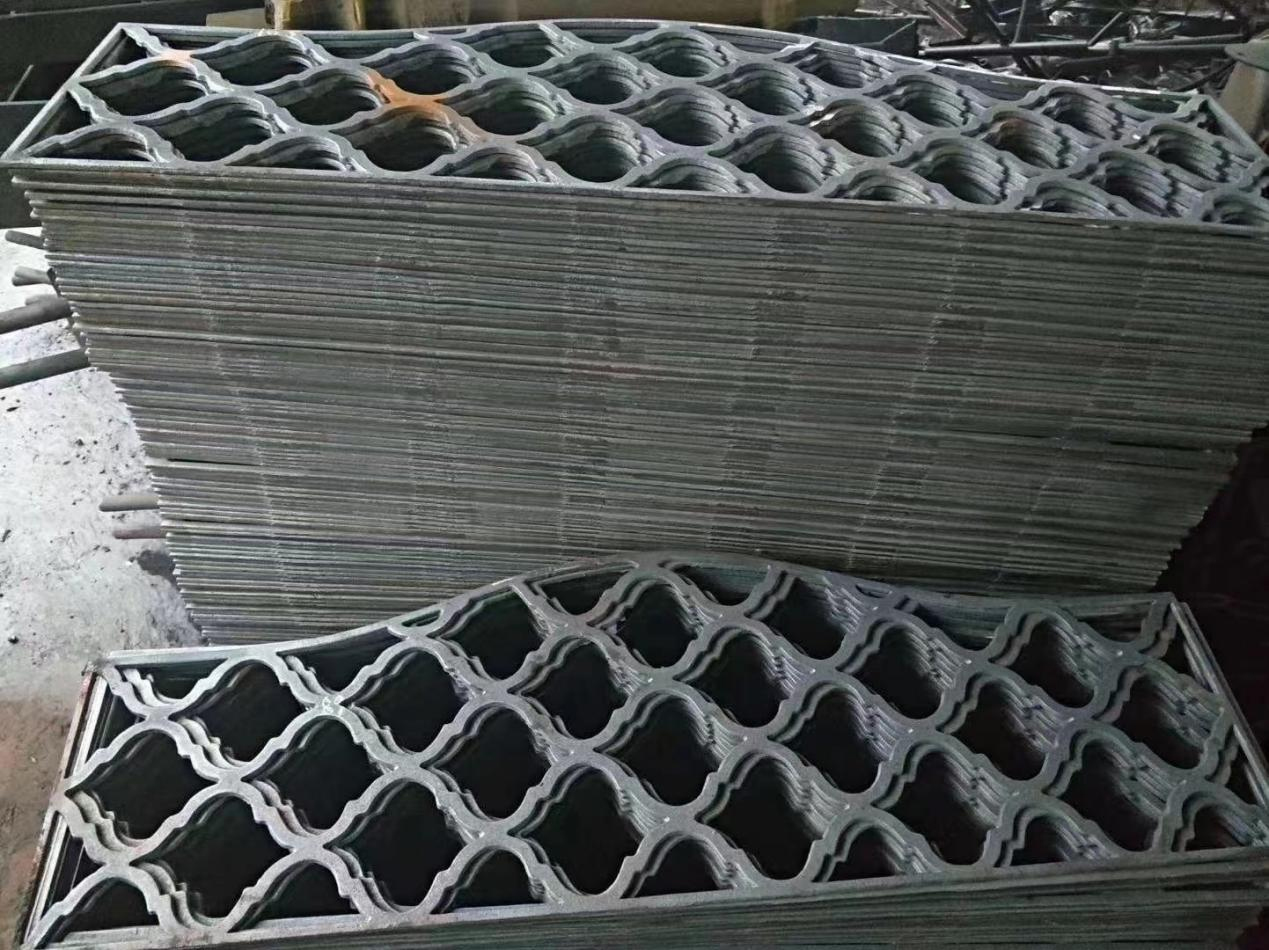

Garden chairs

The park chair is a product for passers-by to rest outdoors, and is mostly used in parks, communities, large playgrounds, shopping plazas, and public places. With the development of the times, park chairs have entered most small and medium-sized cities. Become a beautiful landscape of the city. It brings convenience to people and makes the environment more harmonious. Most park chairs are composed of two parts: a chair bar and a chair foot.

The wrought iron chair is not only made of solid materials, but also carries the artistic atmosphere from ancient times to the present. Smooth lines, perfect color matching make people feel good. At the same time, it also has strong anti-corrosion and oxidation resistance.

We can make park chairs in a variety of different materials and patterns, from small to large, from simple to complex, to meet the different needs of customers.

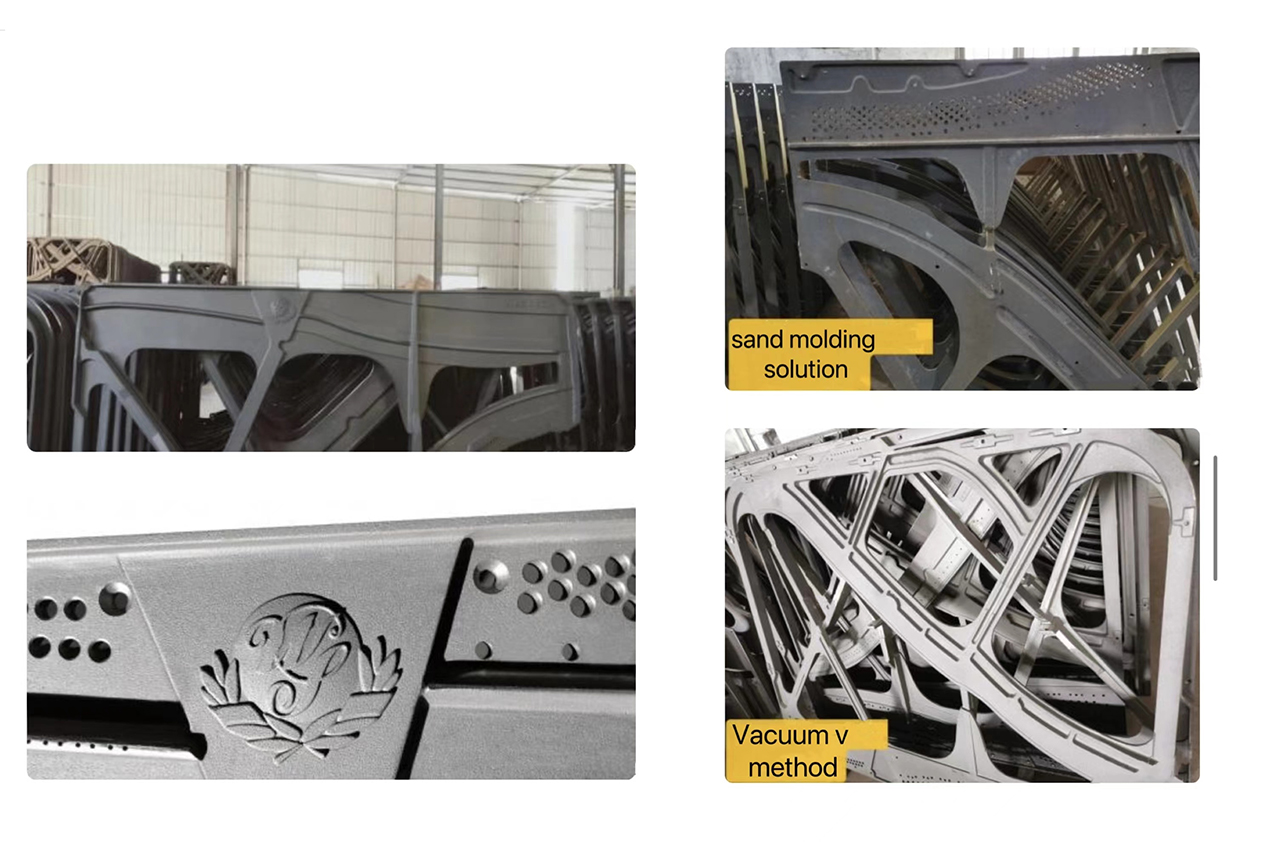

Piano frame

The modern piano cast iron plate, also known as the skeleton, is the main part of the piano that fixes the strings and the heart of the piano. Its quality directly affects the sound and even the life of the piano, so it has a high internal and external appearance of the piano cast iron plate. production standards. The piano frames we manufacture adhere to the quality and requirements of the market for pianos. In the casting process of iron plates, vacuum casting technology and sand casting technology have been applied to the production of piano cast iron plates. Therefore, we start from vacuum casting technology and sand casting. In the process, the quality of the piano frame can meet the customer's requirements.

Sand casting of piano frame:

Advantages: 1. High bearing capacity and good resonance. 2. The iron plate has higher hardness and strength, which ensures that the piano has a more stable performance and is not deformed. 3. The thickness of the transmitted sound is fuller

Disadvantages: 1. High labor cost and slow production speed. 2. The waste of raw materials is higher and needs to be re-polished.

The iron plate casting technology of the piano originated in Europe and has been passed down for centuries, with a profound historical, cultural and technical heritage. With the rapid development of science and technology, the demand for castings in different industries is constantly changing. Vacuum castings have uniform density, no air bubbles, and elegant shapes are mainly used in small parts or jewelry with fine details. The main function of the piano iron plate is to bear the load and give the piano strong support. Therefore, the piano, as always, adopts the sand-casting iron plate casting technology. In concert venues, artists often opt for grand pianos in the traditional sand-cast iron plate technique.

Best Use For Ductile Iron Castings

Due to their increased strength and ductility, these types of castings are best used for:

- Value Bodies

- Compressor Valves

- Couplings

- Sprocket Wheels

- Hydraulic Valves & Cylinders

- Structural Brackets

- Rollers

- Cable Drums

- Frames

- Pumps

- Crankshafts

- Camshafts

- Exhaust Manifolds

- Machine frames

- Flanges

- Hubs

- Gear Boxes

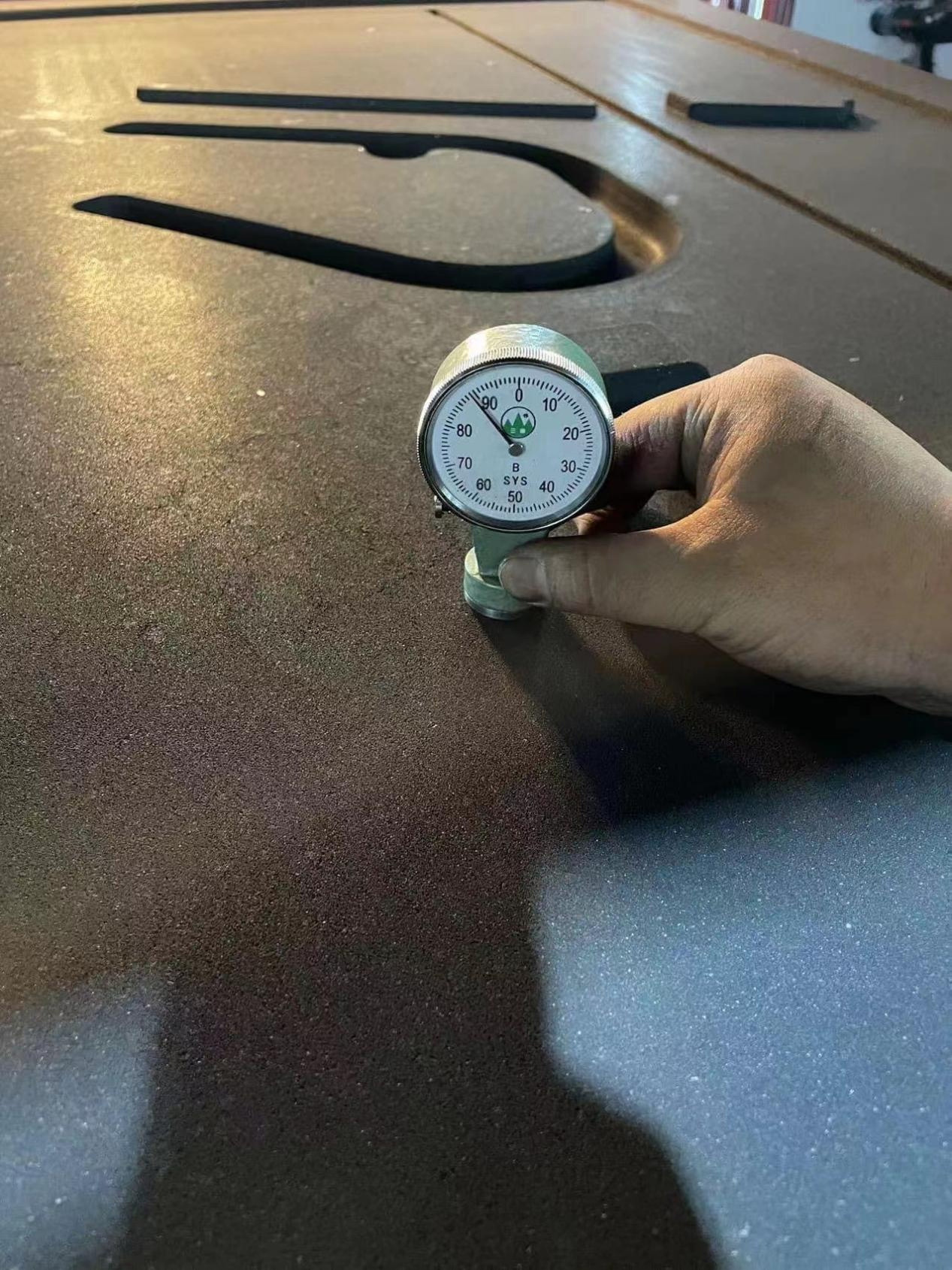

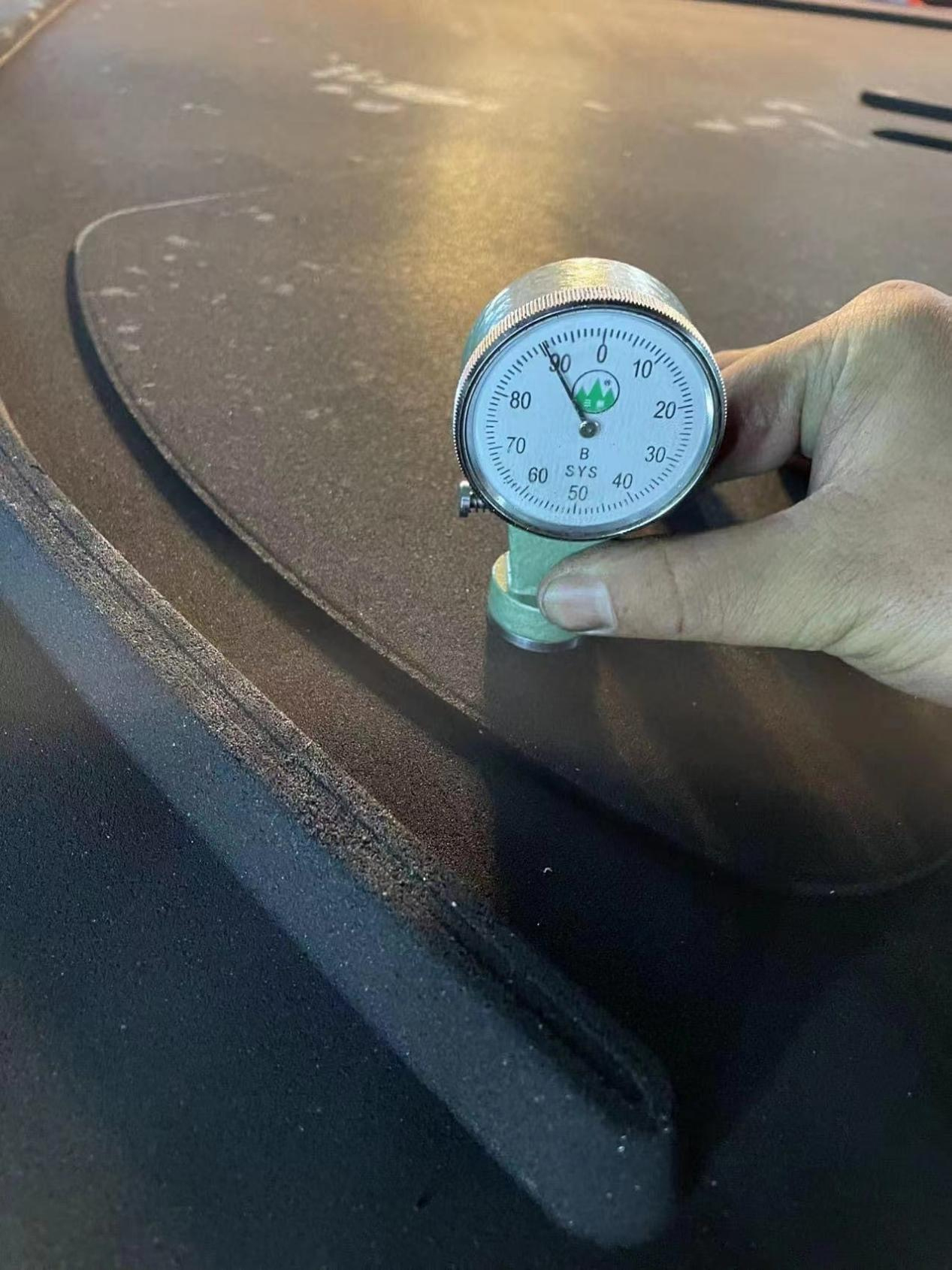

Ductile Iron Casting Foundry

Looking for a partner to assist with ductile iron part casting? Our team of experts work with design engineers to adequately determine the best method for part production.

OEMs can typically reduce costs up to 60% by converting to a casting. Contact Ferroloy today and let us show you how.

The ductile iron casting at

Ferroloy is throughly examined by our quality assurance team.

Contact our iron foundry today to discuss a turnkey

solution for you.

Request Information