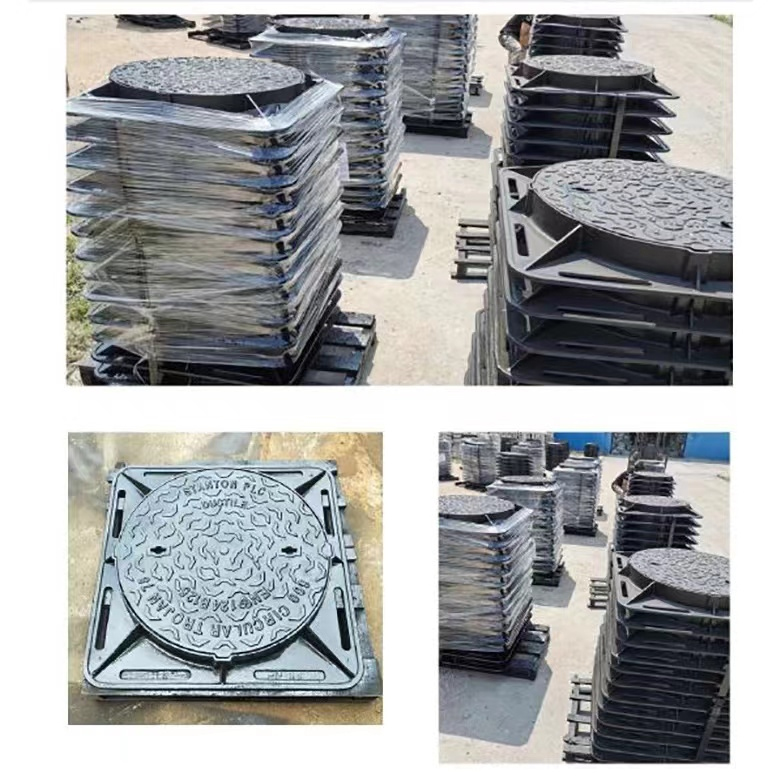

Cast iron manhole covers are divided into ductile iron manhole covers and gray cast iron manhole covers. Generally speaking, ductile iron manhole covers of the same weight are more compressive than gray iron manhole covers. The material used for gray iron manhole covers is generally HT200, and the material used for ductile manhole covers is generally QT500-7.

Due to the spheroidal graphite microstructure of iron, cast iron is superior to cast steel in terms of reducing vibration, so it is more conducive to reducing stress. An important reason for choosing cast iron is that iron material is less expensive than cast steel. The low cost of cast iron makes this material more popular, the casting efficiency is higher, and the machining cost of iron is lesser.

Best Use For Ductile Iron Castings

Due to their increased strength and ductility, these types of castings are best used for:

- Value Bodies

- Compressor Valves

- Couplings

- Sprocket Wheels

- Hydraulic Valves & Cylinders

- Structural Brackets

- Rollers

- Cable Drums

- Frames

- Pumps

- Crankshafts

- Camshafts

- Exhaust Manifolds

- Machine frames

- Flanges

- Hubs

- Gear Boxes

Ductile Iron Casting Foundry

Looking for a partner to assist with ductile iron part casting? Our team of experts work with design engineers to adequately determine the best method for part production.

OEMs can typically reduce costs up to 60% by converting to a casting. Contact Ferroloy today and let us show you how.

The ductile iron casting at

Ferroloy is throughly examined by our quality assurance team.

Contact our iron foundry today to discuss a turnkey

solution for you.

Request Information