Lost foam casting (also known as solid casting) is made of foamed plastic (EPS, STMMA or EPMMA) polymer materials into a solid mold with exactly the same structure and size as the parts to be cast, and is dipped and coated with refractory paint (strengthened). , smooth, breathable) and dried, buried in dry quartz sand and subjected to three-dimensional vibration modeling, pouring molten metal into the casting sand box under negative pressure, so that the polymer material model is heated and gasified and extracted, and then is A new casting method for the production of castings by liquid metal replacing the one-time shape casting new process formed after cooling and solidification.

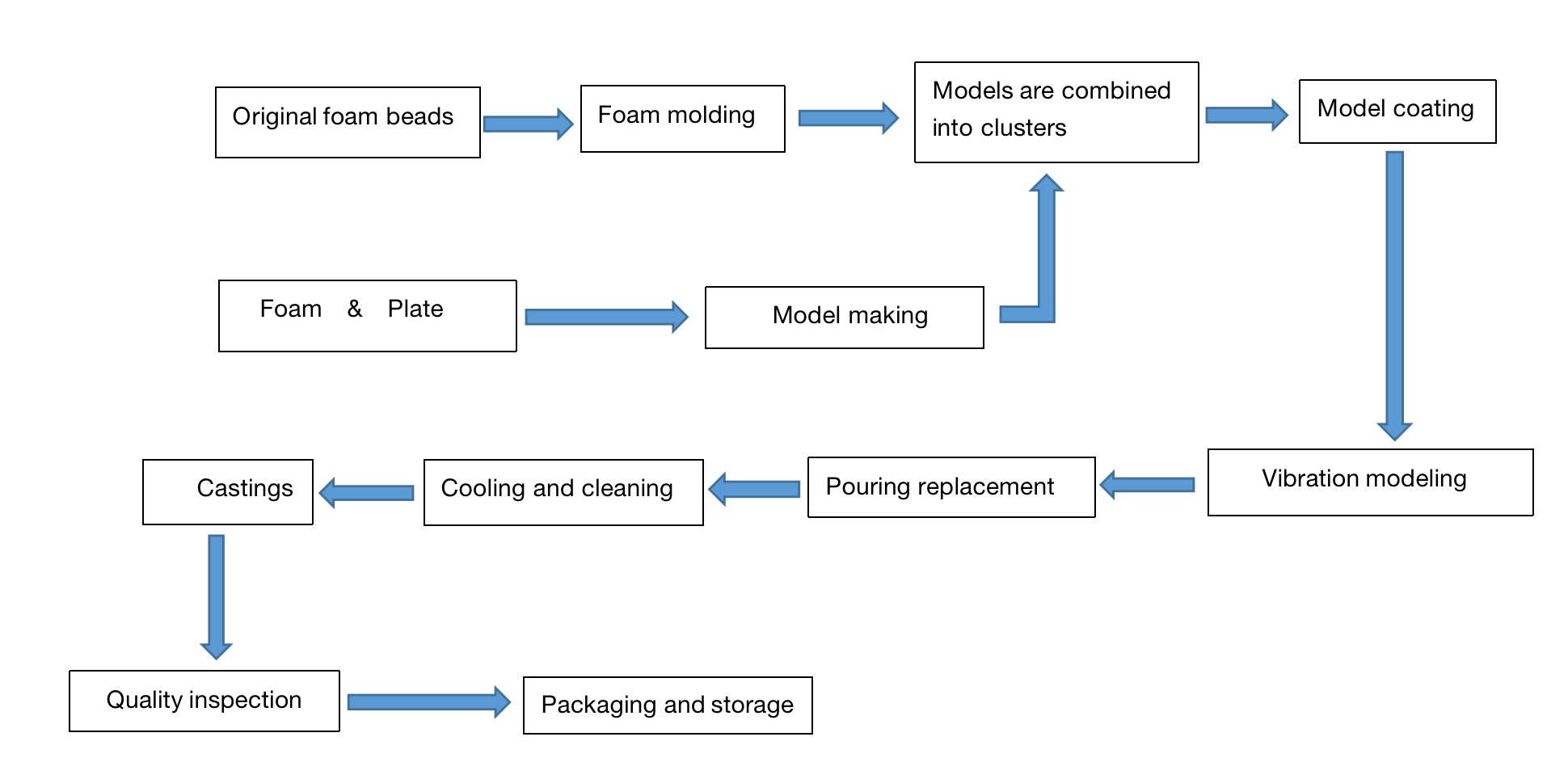

Introduction of lost foam casting process:

1. Selection of foam beads:

There are three types of foam beads for lost foam casting.

① Expandable polystyrene resin beads (referred to as EPS);

② Expandable methyl methacrylate and styrene copolymer resin beads (referred to as STMMA); ③ Expandable polymethyl methacrylate resin beads (abbreviated as EPMMA).

Expandable polystyrene resin beads (EPS) are commonly used for casting non-ferrous metals, gray iron and general steel casting.

Bead characteristics: translucent beads, pre-foaming ratio of 40~60, particle size of 0.18~0.80mm (6 sizes),

Generally, the particle size of the original beads selected is less than or equal to 1/9 ~ 1/10 of the minimum wall thickness of the casting.

2. Model making:

There are two cases:

◎Made from foam beads: pre-foaming - curing - foam molding - cooling out of the mold

①Pre-foaming

Before the EPS beads are added to the mold, they must be pre-expanded to expand the beads to a certain size.

The pre-foaming process determines the density, dimensional stability and accuracy of the model and is one of the key links. There are three methods for EPS bead pre-foaming: hot water pre-foaming, steam pre-foaming and vacuum pre-foaming. Vacuum pre-foamed beads have high foaming rate, dry beads, and are widely used.

②Aging

The pre-expanded EPS beads are placed in a dry, ventilated silo for a certain period of time. In order to balance the external pressure in the bead cells, make the beads have elasticity and re-expansion ability, and remove the water on the surface of the beads. The aging time is 8 to 48 hours.

③Foam molding

Fill the pre-foamed and cured EPS beads into the cavity of the metal mold, and heat the beads to expand again, fill the gaps between the beads, and make the beads fuse with each other to form a smooth surface, that is, the model. It must be cooled before the mold is released, so that the model is cooled to below the softening temperature, and the mold can be released after the model is hardened and shaped. After the mold is released, there should be time for the model to dry and dimensionally stabilize. There are two types of equipment: steam cylinder and automatic forming machine.

◎ Made of foam plastic sheet: foam plastic sheet - resistance wire cutting - bonding - model

For simple models, the resistance wire cutting device can be used to cut the foam plastic sheet into the required model.

For complex models, first use a resistance wire cutting device to divide the model into several parts, and then glue it to make it a whole model.

3. The models are combined into clusters:

It is to combine the self-processed (or purchased) foam model with the pouring riser model to form a model cluster. This combination is sometimes carried out before the coating, and sometimes is carried out when the coating is prepared and buried in the box. It is an indispensable process in lost foam (solid) casting.

Currently used bonding materials: rubber latex, resin solvent and hot melt adhesive and tape paper.

4. Model coating:

The surface of the solid casting foam model must be coated with a certain thickness of paint to form the inner shell of the casting mold. The function of the coating is to improve the strength and rigidity of the EPS model, improve the resistance of the surface of the model to sand scour, prevent the damage of the model surface during the sanding process and the deformation of the model during vibration modeling and negative pressure setting, and ensure the dimensional accuracy of the casting.

For the outsourced special paint for lost foam casting, add water and stir in the paint mixer to obtain a suitable viscosity. The stirred paint is put into the container, and the model group is coated with the methods of dipping, brushing, showering and spraying. Generally, apply twice to make the coating thickness 0.5 ~ 2mm. It is selected according to the type of casting alloy, structural shape and size. The coating is dried at 40~50℃.

5. Vibration modeling:

We introduce a commonly used modeling method (one of two methods).

The process includes the following steps: sand bed preparation - placing EPS model - filling sand - sealing and shaping

①Sand bed preparation

Place the sandbox with the extraction chamber on the shaker and clamp it tightly. Put a certain thickness of bottom sand at the bottom (generally the thickness of the sand bed is more than 50~100mm), and the vibration is tight.

Molding sand is dry quartz sand without binder, filler, and water. The temperature of ferrous metal is high, coarser sand can be used, and finer sand is used for aluminum alloy. Molding sand should be used repeatedly after treatment.

The sand box is a sand box with a single-sided opening, an air extraction chamber or an air extraction pipe, and a hoisting or walking mechanism.

②Place EPS model

After vibrating, the EPS model group is placed on it according to the process requirements, and sand is fixed to fix it.

③ Sand filling

Add dry sand (several sanding methods), and at the same time apply vibration (X, Y, Z directions), the time is generally 30~60 seconds, so that the sand fills all parts of the model, and the bulk density of the molding sand increases.

④Seal setting

The surface of the sand box is sealed with plastic film, the inside of the sand box is pumped into a certain vacuum with a vacuum pump, and the sand grains are "bonded" together by the difference between the atmospheric pressure and the pressure inside the mold, so as to keep the mold from collapsing during the pouring process, which is called "Negative pressure setting. It is more commonly used.

6. Pouring replacement

The EPS model generally softens at around 80°C, and decomposes at 420~480°C. The decomposition products have three parts: gas, liquid and solid. The thermal decomposition temperature is different, and the content of the three is different.

When the solid mold is poured, under the heat of the liquid metal, the EPS model undergoes pyrolysis and gasification, and a large amount of gas is generated, which is continuously discharged through the coating sand and discharged to the outside, forming a certain air pressure in the mold, the model and the metal gap. The metal continuously occupies the position of the EPS model and advances forward, and the replacement process of the liquid metal and the EPS model occurs. The end result of the displacement is the formation of a casting.

The pouring operation process adopts slow-fast-slow. And keep continuous pouring to prevent the pouring process from being cut off. After pouring, the mold vacuum is maintained for 3 to 5 minutes and then the pump is stopped. The pouring temperature is 30~50℃ higher than that of sand casting.

7. Cooling and cleaning

After cooling, it is the easiest to shake out the sand in solid casting. The casting can be lifted out of the sand box by tilting or directly from the sand box, the casting and the dry sand are naturally separated. The separated dry sand is treated and reused

Best Use For Ductile Iron Castings

Due to their increased strength and ductility, these types of castings are best used for:

- Value Bodies

- Compressor Valves

- Couplings

- Sprocket Wheels

- Hydraulic Valves & Cylinders

- Structural Brackets

- Rollers

- Cable Drums

- Frames

- Pumps

- Crankshafts

- Camshafts

- Exhaust Manifolds

- Machine frames

- Flanges

- Hubs

- Gear Boxes

Investment castings and sand mold castings foundry

Looking for a partner to assist with castings? Our team of experts work with design engineers to adequately determine the best method for part production.

OEMs can typically reduce costs up to 60% by converting to a casting. Contact Z&Z today and let us show you how.

The castings of Z&Z foundry is throughly examined by our quality assurance team.

Contact our iron foundry today to discuss a turnkey

solution for you.

Request Information